Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Agrochemical Functions

- Cleaning Ingredients Functions

- Industrial Additives Functions

- Pharma & Nutraceuticals Functions

- Technologies

- Product Families

- Producer Product Number

- 30042761

Features & Benefits

- Labeling Claims

- HII Features

- Recommendation for Pump and Piping Equipment

- Sealing and pipelines e.g.: Aramide fiber with special nitrile rubber (NBR)-binders (AFM 34)

- Pump e.g.:

- Gear Pump (positive displacement)

- Constructional material: Stainless steel for the housing/casing

- Plain/antifriction gearing made from tungsten carbide with Ni-binders or made

- from silicon carbide

- Output/Capacity: up to 50 mM/h

- Static head: 60 m

- Pump sealing e.g.:

- Metallic parts: stainless steel

- Slip rings on the product side: tungsten carbide or silicon carbide

- O-rings on the product side: Viton, double, PTFE coated

- Slip rings on the atmospheric side: carbon/cast chrome steel

- O-rings on the atmospheric side: Viton

- Interlock medium: Water/Glysantin

- Diskharching temperature: approx. 60°C

- Level indication: Pressure difference measurement

- Key Attributes

- Polymeric Dispersing Agents have the potential to inhibit incrustation and scale formation.

- This is a result of their ability to disperse suspended solids.

- Boosts detergency overcoming deficiencies seen when phosphates are removed from formulations.

Applications & Uses

- Markets

- Applications

- Applicable Processes

- Home Care Applications

- I&I Cleaning Applications

Properties

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

- Quality Standards

Technical Details & Test Data

- Technical Information

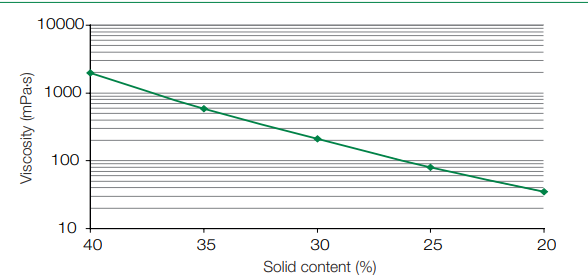

The viscosity of Sokalan® CP 5 is mainly influenced by the concentration. Figure 1 shows the differences in viscosity as a function of the concentration.

Figure 1: Viscosity of Sokalan® CP 5 at different concentrations at 23°C

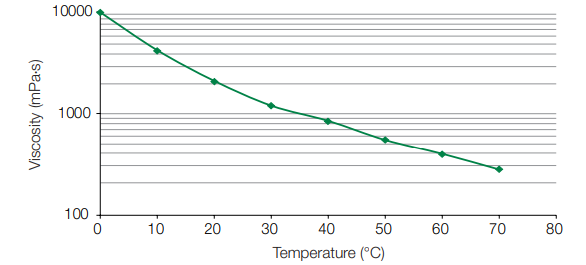

In terms of impact of temperature on the viscosity figure 2 indicates this behavior for Sokalan® CP 5.

Figure 2: Viscosity of Sokalan® CP 5 at temperatures between 0 - 70°C

Safety & Health

- Safety Conditions

We are not aware of any ill effect that can result from using Sokalan® CP 5 for the purpose for which it is intended and from processing it in accordance with current practices. According to the experience that we have gained over many years and other information at our disposal, Sokalan® CP 5 does not exert harmful effects on health, provided it is used properly, due attention is given to the precautions necessary for handling chemicals, and the information and advice given in our Safety Data Sheets are observed.

Packaging & Availability

- Country Availability

- Packaging Type

- Packaging Information

- 1200kg Composite - IBC (PE/Metal)

- 150KG Plastic drums

- Bulk

Storage & Handling

- Storage Condition

Handling Only Packaged Goods

- Sokalan® CP 5 should be stored in a dry place in its original sealed packaging.

- Sokalan® CP 5 can slighty separate during the storage time. The product must be homogenized before it is processed. It must be mixed sufficiently prior to use.

- The storage temperature must be between min. + 5°C and max. +25°C. At low temperatures (approx. + 5°C) Sokalan® CP 5 forms crystals and becomes solid. Drums or IBCs containing solidified product or liquid that have begun to precipitate or separated should be reconstituted by gentle heating, preferably in a heating cabinet. Warming up to max. +25°C allows the product to become liquid again. It must be mixed sufficiently prior to use. This also applies if drums are heated by external electrical elements. Internal electrical elements should not be used because of the localized anomalies in temperature that they can cause.

- Sokalan® CP 5 must be protected from sunlight and high temperatures to avoid discoloration and the formation of surface films.

- Sokalan® CP 5 must be blanketed with nitrogen if it is stored to prevent air contact. Air contact can cause discoloration.

- Please refer to the latest Safety Data Sheet for detailed information on product safety.

Handling Only Bulk Containers

- The storage temperature for bulk product must be between min. +40°C and max. +60°C. Storage temperatures above + 60°C cause an increase of the color number. At low temperatures (approx. < +5°C) Sokalan® CP 5 forms crystals and becomes solid.

- Sokalan® CP 5 can slighty separate during the storage time. The product must be homogenized before it is processed. It must be mixed sufficiently prior to use.

- Sokalan® CP 5 must be protected from high temperatures (> +60°C) to avoid discoloration and the formation of surface films.

- Sokalan® CP 5 must be blanketed with nitrogen if it is stored in heated tanks (at max. +60°C) to prevent air contact. Air contact can cause discoloration. Constant, gentle stirring helps to prevent it being discolored as a result of prolonged contact with electrical elements or external heating coils.

- Please refer to the latest Safety Data Sheet for detailed information on product safety.

Materials:

The following materials can be used for tanks and drums:

a) Stainless steel 1.4541 - AISI 321 X6 CrNiTi 18-10)

b) Stainless steel 1.4571 - AISI 316 Ti (X6 CrNiMoTi 17-12-2)

c) Stainless steel 1.4306 - AISI 304 L (X2 CrNi 19-11)

d) HDPE - high density polyethylene LDPE - low density polyethyleneShelf Life:

Sokalan® CP 5 has a shelf life of at least 24 months in its original packaging.